Well I am either going to make a Big Fool out of myself( likely  ) or the,

) or the,

Biggest Himalayan ever!

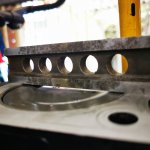

Here is the Barrel,

And to fill that "Hole"

And to top it of,

A bigger Combustion Chamber with Bigger Valves( like 37 and 39.5(might check that!) with the seat cut to suit and the Ports matched and "Enlargened".

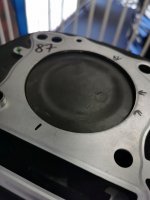

Not much room for an oversize but I do have a thicker Liner as back up, this is the Top Veiw ( siera Vista?)

The back up plan, a bit more Meat here!

Inlet has been made shiny and bigger.

Manifold is going to be attached to a 37mm Throttle Body.

I found it in amongst my spare parts when looking for something else! the only concern is I thought it was on my 443 .

.

Got a back up plan for the airfilter as well.

Thanks to @barima I also have.,

A Spacer, Lazer cut or somesuch which made from Aluminum should not slow me down much.

So by the time this is fitted the Cam will be some,,,

6mm Vertically away from where it normally sits!

So a Cam Chain with 2 extra Links is required.

@barima again

a crowd. funding site could be set up but they would skim too much so just PayPal my email account, I don't wish to make a Big deal out if it X2

X2

Biggest Himalayan ever!

Here is the Barrel,

And to fill that "Hole"

And to top it of,

A bigger Combustion Chamber with Bigger Valves( like 37 and 39.5(might check that!) with the seat cut to suit and the Ports matched and "Enlargened".

Not much room for an oversize but I do have a thicker Liner as back up, this is the Top Veiw ( siera Vista?)

The back up plan, a bit more Meat here!

Inlet has been made shiny and bigger.

Manifold is going to be attached to a 37mm Throttle Body.

I found it in amongst my spare parts when looking for something else! the only concern is I thought it was on my 443

Got a back up plan for the airfilter as well.

Thanks to @barima I also have.,

A Spacer, Lazer cut or somesuch which made from Aluminum should not slow me down much.

So by the time this is fitted the Cam will be some,,,

6mm Vertically away from where it normally sits!

So a Cam Chain with 2 extra Links is required.

@barima again

a crowd. funding site could be set up but they would skim too much so just PayPal my email account, I don't wish to make a Big deal out if it