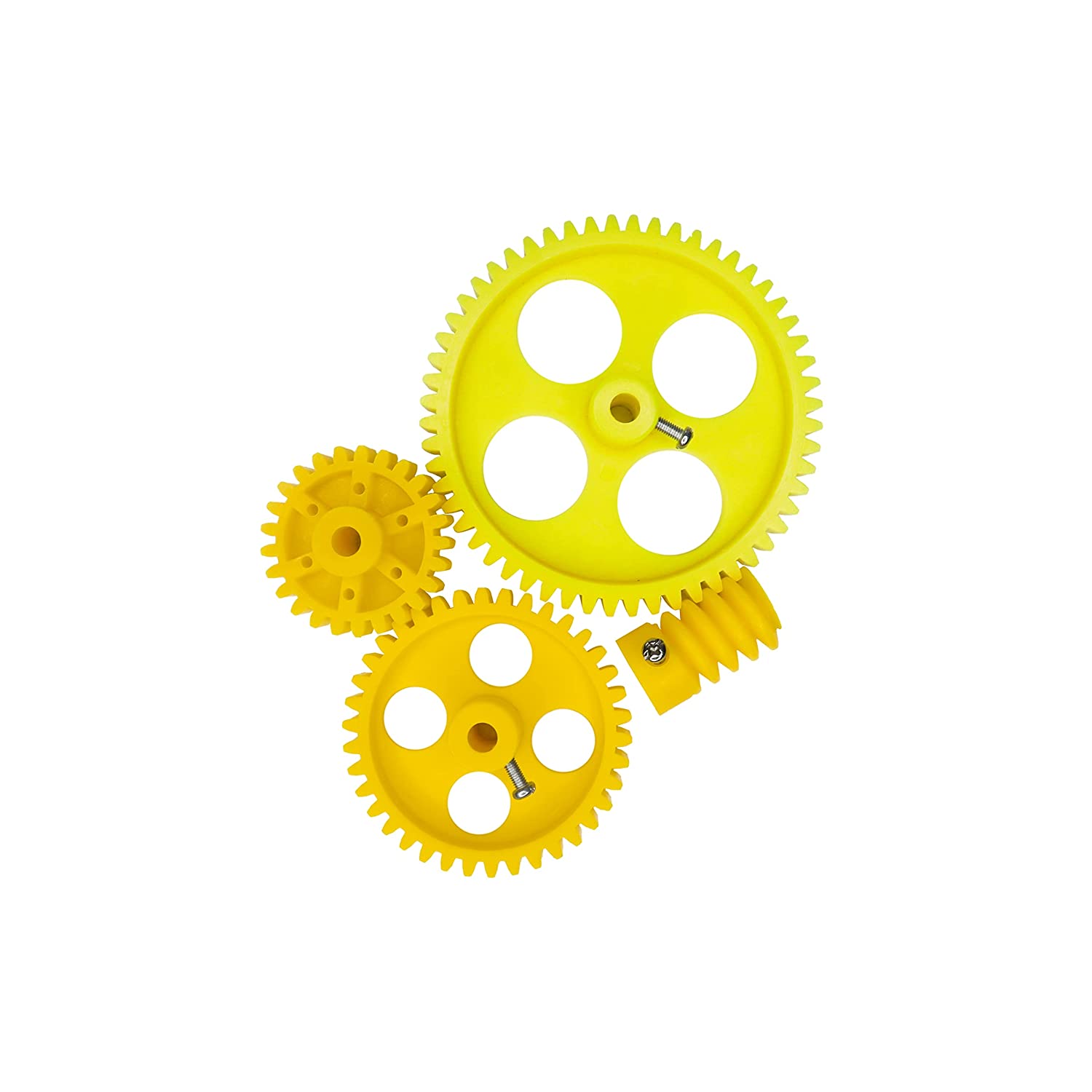

the 3d print is plastic - will that do? I thought we are looking for metal in the real application (not a model). I can try to find an Indian manufacturer for the metal partI will send you the STL of the idle gear asap. Since i know you have access to a 3D printer now

I might have to redesign it though because i think i can do better now...

I also ordered an industry standard gear from china to keep things going. You can order even order the right bore size so it should directly fit to the gearbox axle. Lets see in which issues we run when this gear arrives. It's definately not the the price

sounds good, unfortunately most Chinese sources are unavailable in India like aliexpress etc. due to politics.