There is a discussion about the details of the process happening in the fb page in German, so be prepared to use google translate or Bart (better) to get the picture, I add the initial announcement here (editing out German humor):

Anyone who knows PU (polyurethane) from the automotive sector as a replacement for rubber chassis bushings can understand the enthusiasm for this material. The wear resistance is enormous, PU basically doesn't age, nor is its mechanical resilience very high. After I exchanged ideas with Patrick Lediner...also a fan of PU in the automotive sector, the enthusiasm was there immediately and off we went:

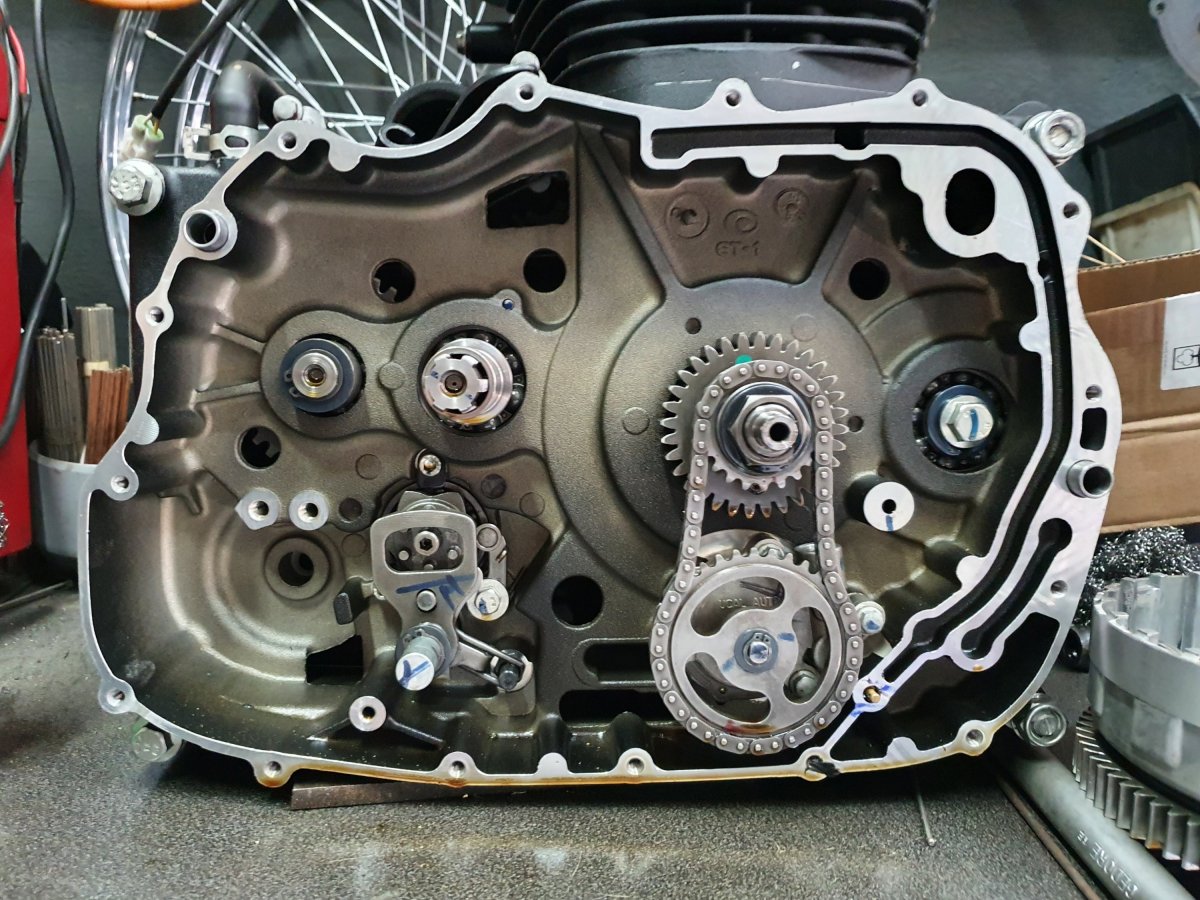

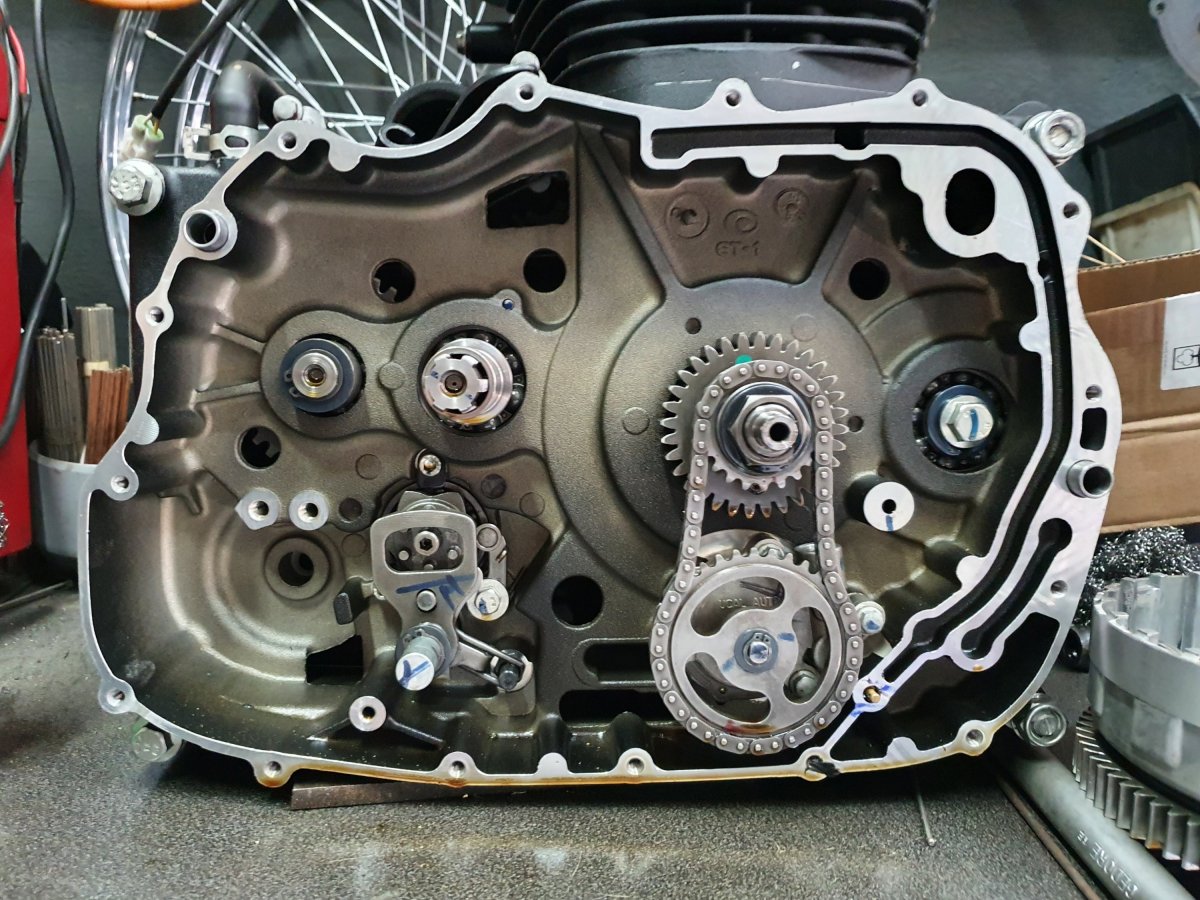

The Shore D value (elasticity) was measured on the new part and liquid PU of the appropriate hardness plus hardener was ordered. Molding the original rubber seemed too complicated due to the undercuts and would have required a two-part silicone mold - so simplify it! A spare wheel without a brake disc was aligned horizontally crosswise on a hot plate and the volume was determined with water. Then carefully brush it with release agent, mix the PU and quickly pour it into the warmed hub, put the chain wheel carrier in exactly aligned, put the axle in for centering and let it rest.

Finally, the experiment resulted in a donut that could be removed from the mold and was installed today. The first 1.5 hour test was successful - now it's time for the long-term test, which I'm quite calm about.

Note: PU is not exactly cheap, the pot life is somewhere around 3 - 4 minutes and somewhere release agent was forgotten (you know construction foam - it's the same thing just without foaming) Gloves, mask and good ventilation are mandatory because who likes to inhale superglue!

https://www.facebook.com/groups/828...1707081721048500¬if_t=group_comment_follow

royalenfieldhimalayan.home.blog

royalenfieldhimalayan.home.blog

royalenfieldhimalayan.home.blog

royalenfieldhimalayan.home.blog